How to Install ANNAPOLIS WALL MOUNT SENSOR FAUCETS OIL RUBBED BRONZE FINISH | BST-291RB

|

Minimize waste of water, by using the automatic faucet. Immediately reduces water waste by eliminating unnecessary and unattended water flow. Ideal for commercial use applications in public restrooms, restaurants, office building, public facilities, hospitals. Fits all standard US plumbing. Reduces the transfer of germs by preventing cross-contamination and re-contamination of germs and bacteria by not touching the faucets or handles.Cut down on water usage by minimizing waste of water while soaping, lathering, scrubbing and drying hands by eliminating unnecessary and unattended water flow.

|

|

|

|

Features:

|

|

Visit Product Page

|

- infrared sensor operated, touch-free operation

- Water Conserving

- Waterproof sensor

- Battery low LED light indicator

- Advanced circuit design saves electricity and water

- Advanced energy saving design for long lasting battery life.

- Three-year battery life based on 3,000 hand washes per month

- Sensor is not affected by reflections or abnormal lighting

- Self-adapting sensors range

- Battery: 4*'AAA' size cells

- Long life durable body

- Operational water pressure range: 0.05 - 0.7MPa

- ADA Complaint

- Power Supply Options

- Hands-Free Sanitary Operation

- Water supply pipe size: DN15

- Vandal-Resistant Aerator

- Ambient temperature range: 0.1 - 45 degrees

- Automatic 30-Second Time Out

- Highly-Polished, Chrome Plated Cast Brass Bodies

- Low Battery Indicator Light

- In-Line Filter

- Factory Set Sensor Range

.

|

sensor faucet

|

|

|

.

Sensor Activated Faucet Special Features:

- Durable Vandal-Resistant Brass Body; Ideal for Residential as well as commercial high use applications

- Intelligent: with its micro-computer controlling its action, the Electronic faucet will self adjust its best detection zone as per the color and shape of lavatory

- Flashing light indicator; a diagnostic indicators for power up, low battery, and solenoid function.

- Meaning of the codes are described in the installation instructions.

- Convenient to maintain; with built-in strainer to prevent sundries from entering the solenoid valve and the strainer is easy to clean

- Electronic Faucet can be mount to any sink surface.

- ADA Complaint

- Batteries life 8,000 cycles per month and with enough water pressure is approx 5 year service life of the batteries.

- Adjustable sensing range; while the factory range is set about 4"to 5"from the sensor, it can be adjusted.

|

Diameter of inlet pipe

|

DN15

|

|

Diameter of outlet pipe

|

DN15

|

|

Water Pressure

|

0.05Mpa - 0.7Mpa

|

|

Power and Voltage

|

DC.6V

|

|

AC.220V - 50/60Hz

|

|

Power Consumption

|

0.5MW

|

|

<2W

|

|

Detection Zone

|

Factory set 25cm/10" (based on standard inductive board)

|

|

Ambient Temperature

|

1 - 45 ℃ / 33.8 -113 °F

|

|

Degree of protection by enclosure

|

1P56

|

|

|

|

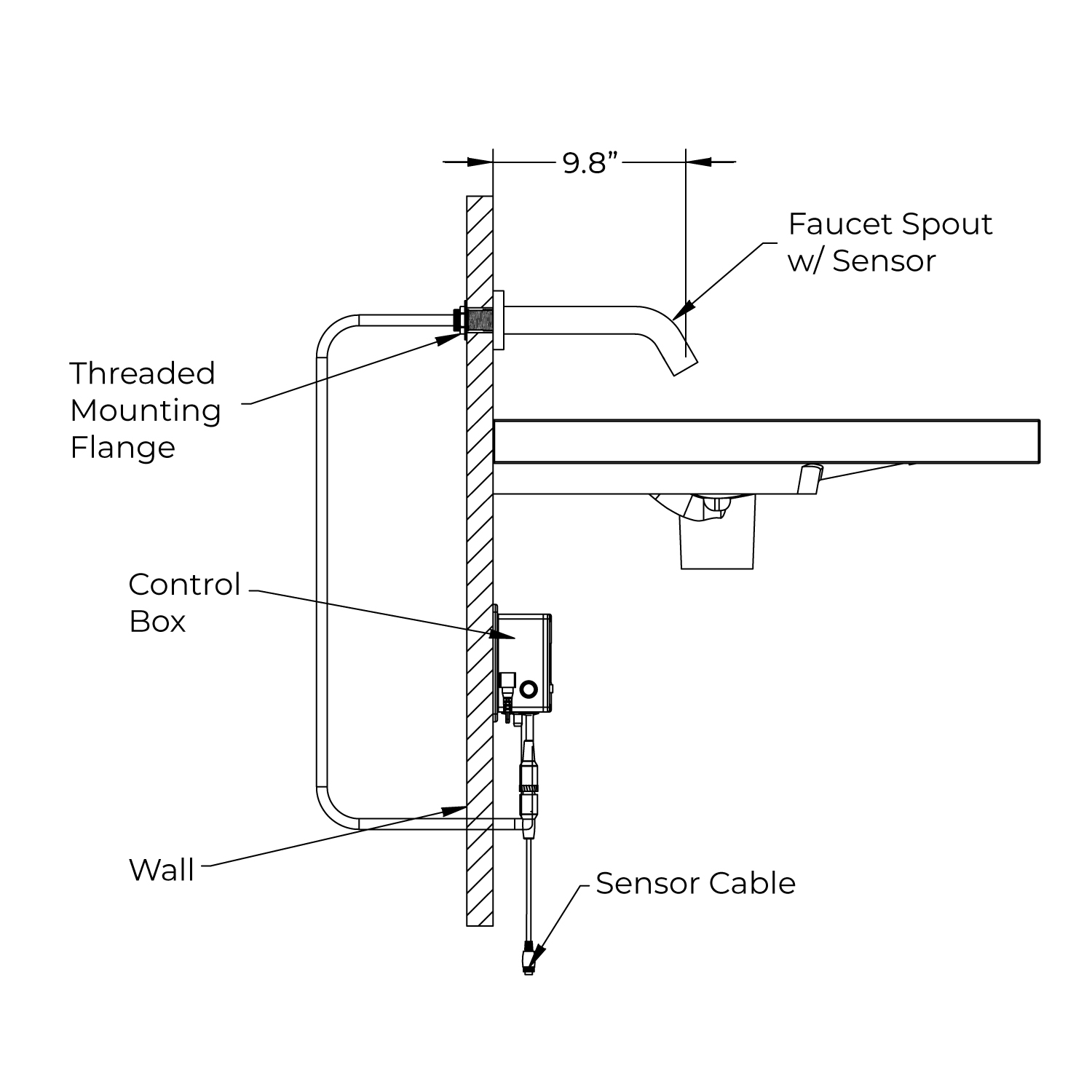

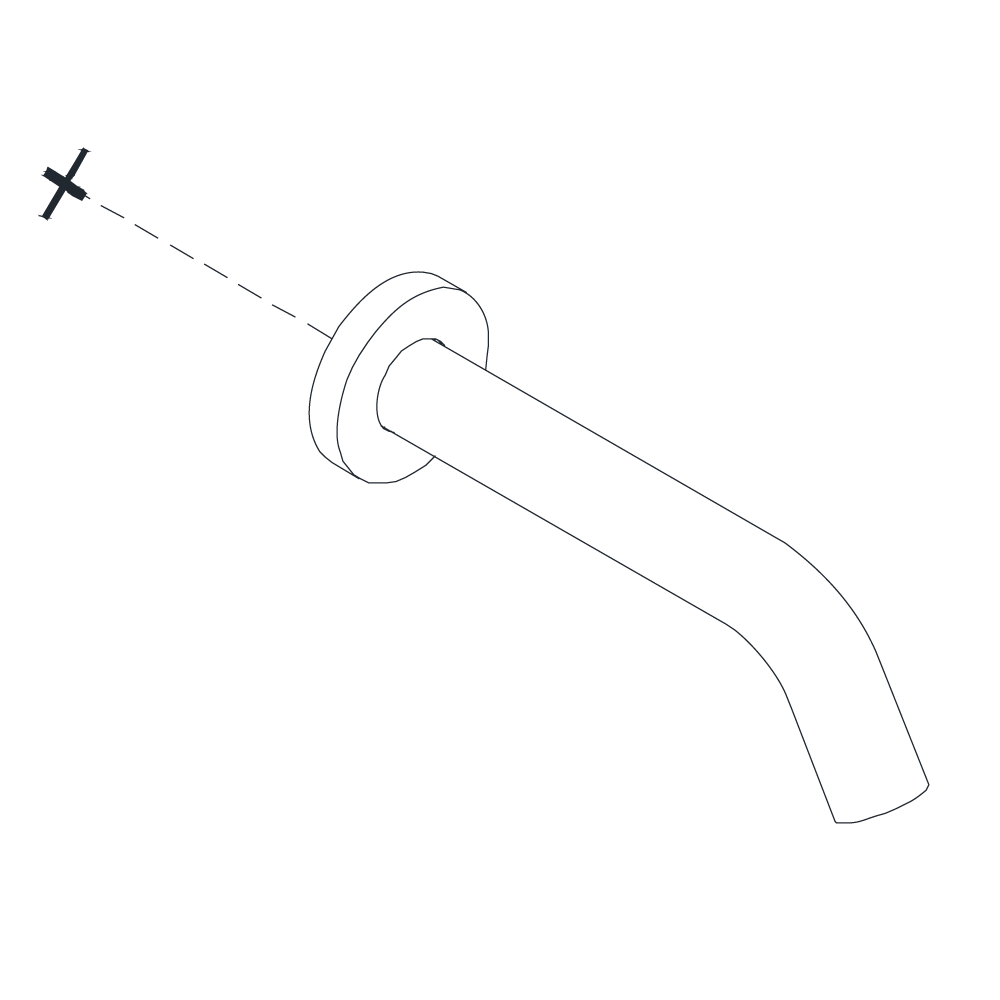

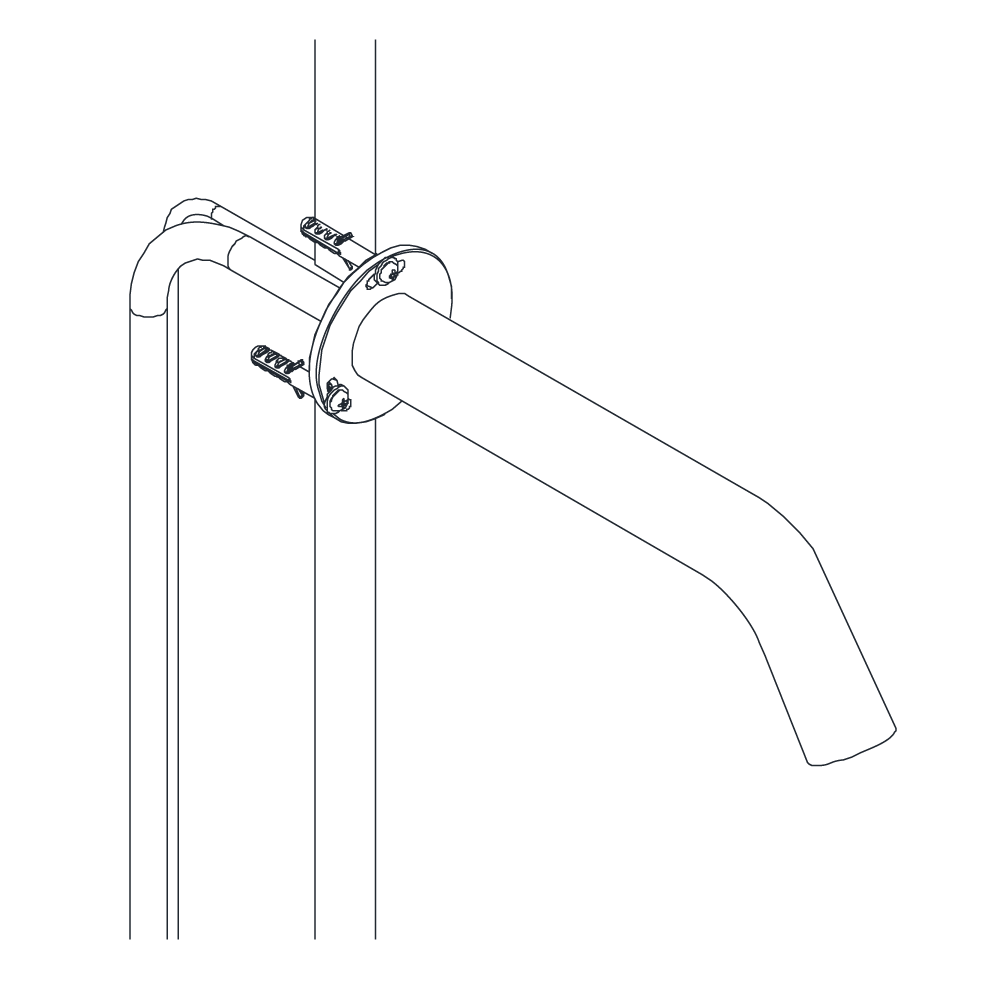

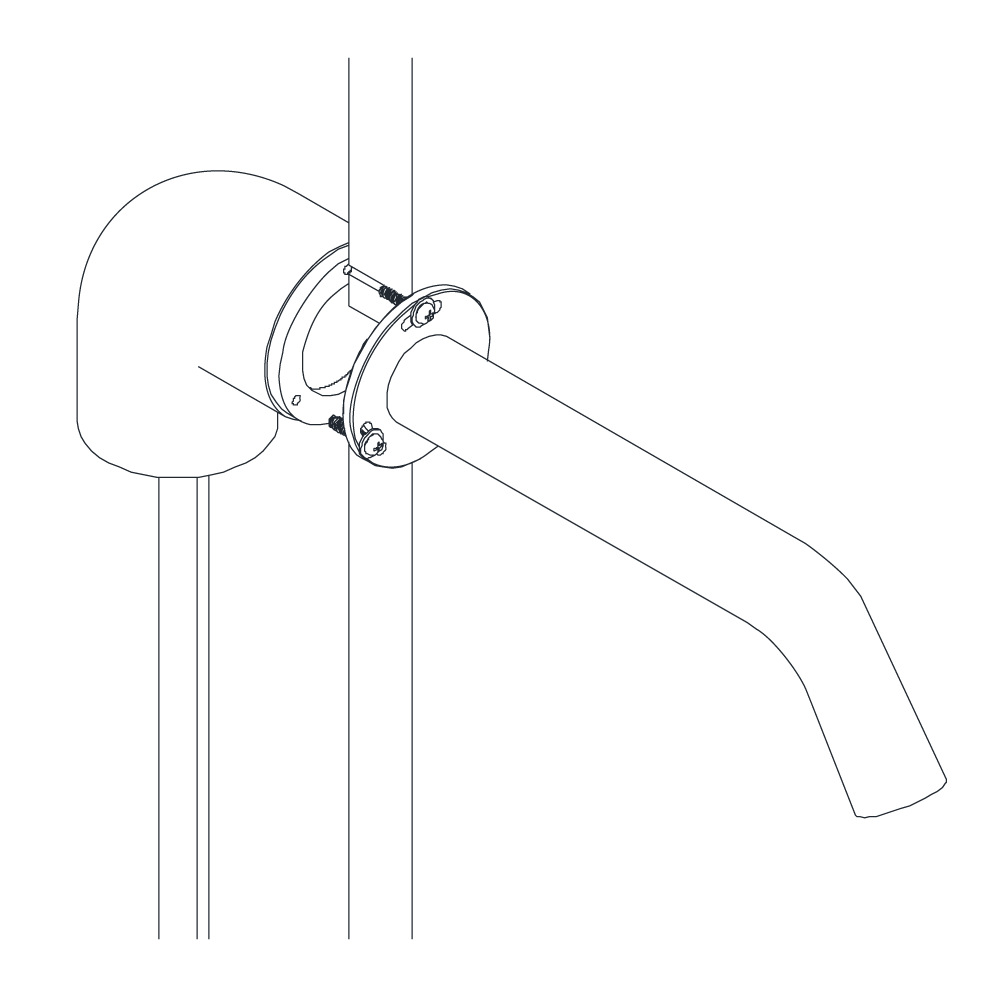

Sensor Faucet Installation Instructions| Step 1: | sensor | Step 2: |

| |

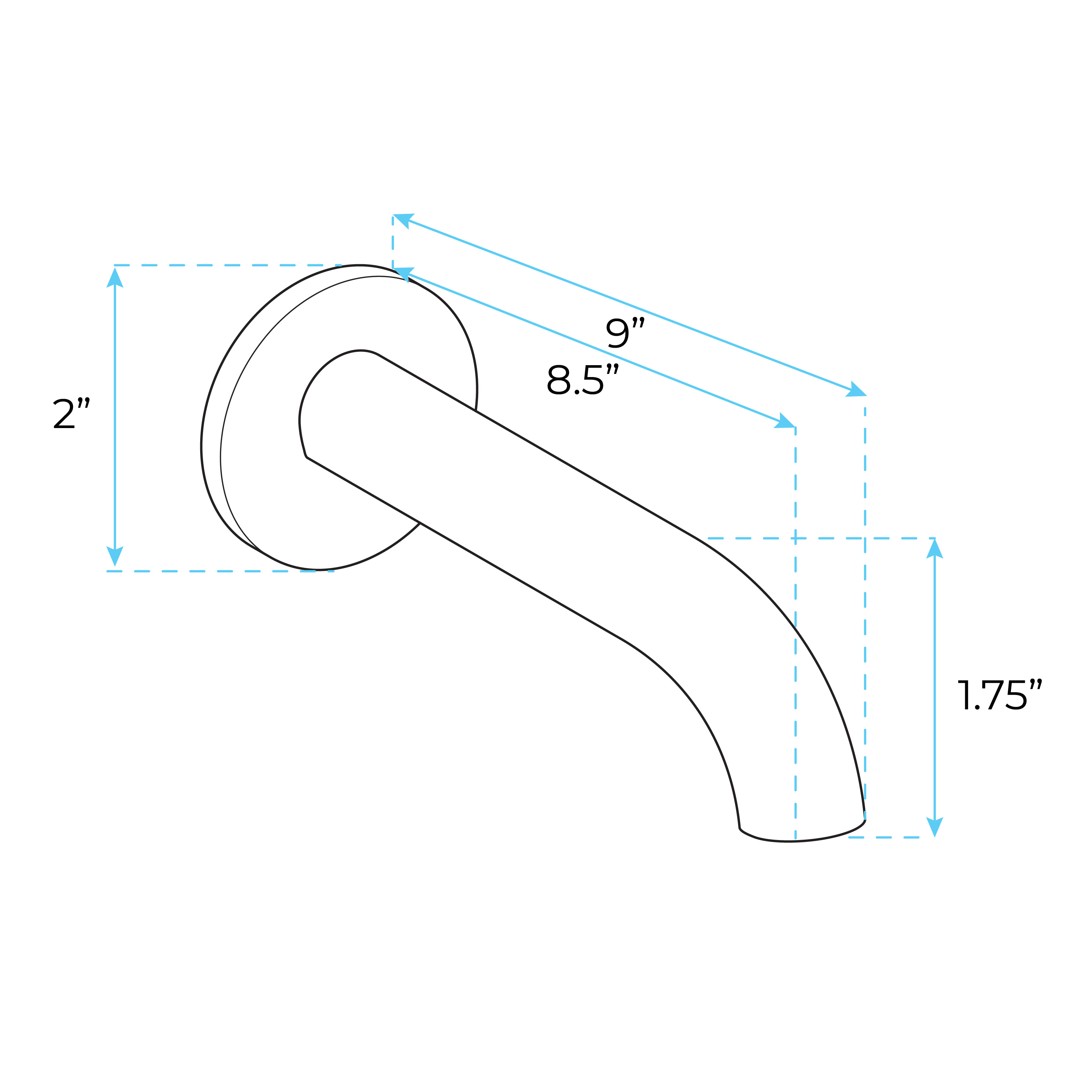

| | | | | Parts: | | Size: |

| |

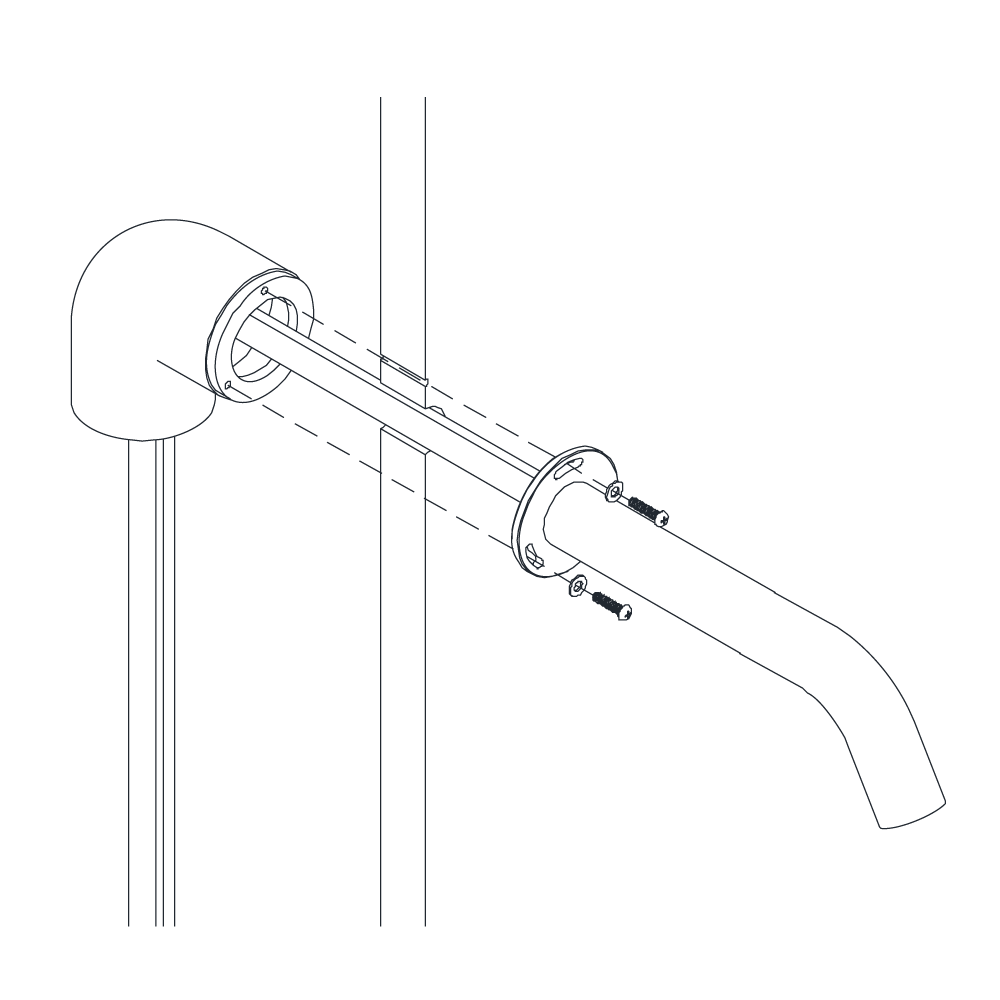

| | | | | Step 3: | | Step 4: |

| |

| | | | | Step 5: | | Step 6: (Drywall Anchor Method) |

| | .png)

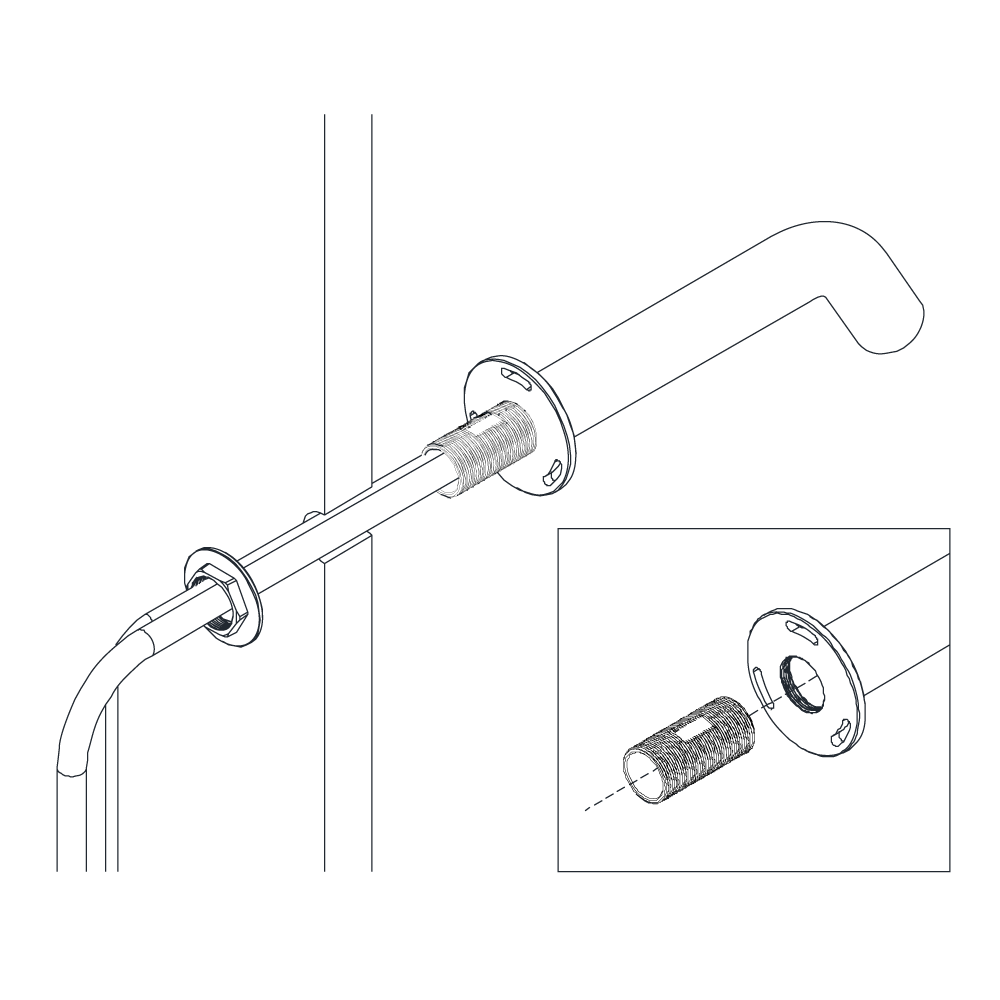

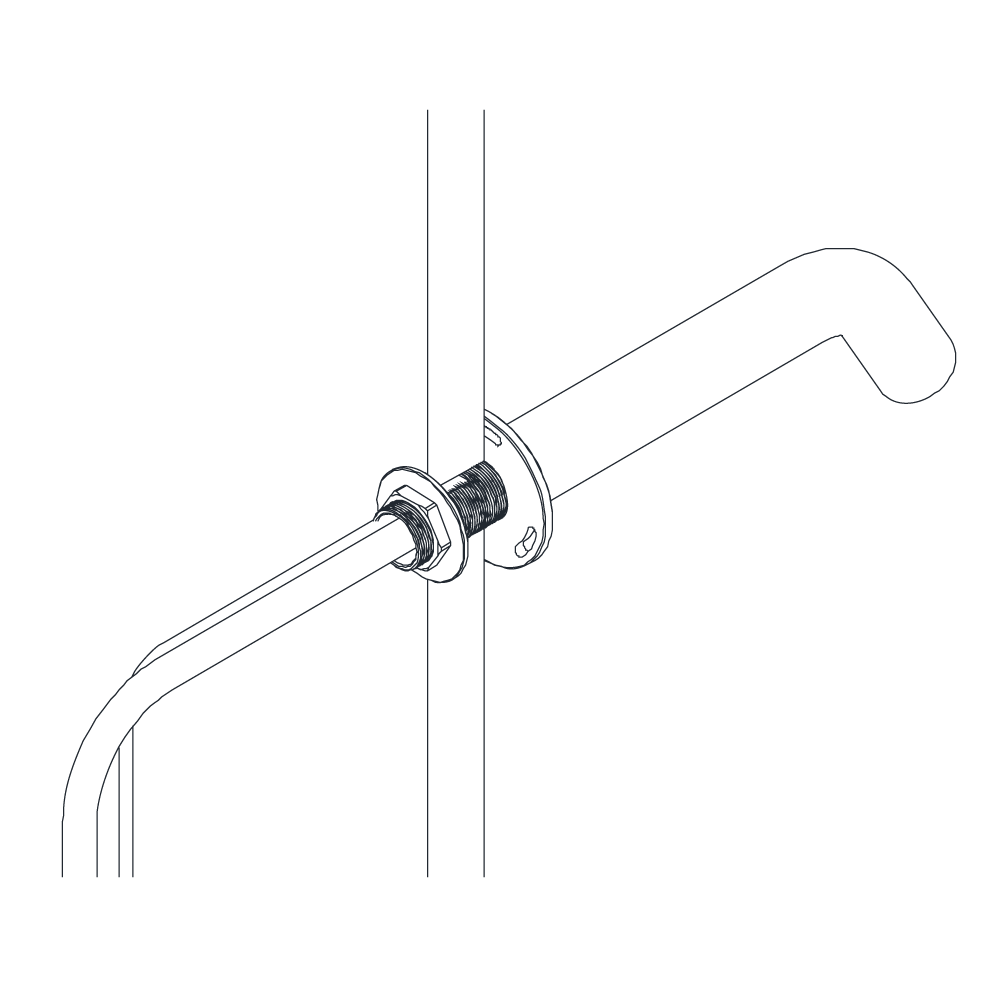

| | | | | Step 7: | | Step 8: (Threaded Shaft Method) |

| |

| | | | | Step 9: | | Step 10: (Elbow Method) |

| |

| | | | | Step 11: | | Step 12: (Plywood Method) |

| |

| | | | | Step 13: | | Step 14: |  | |

| | | |

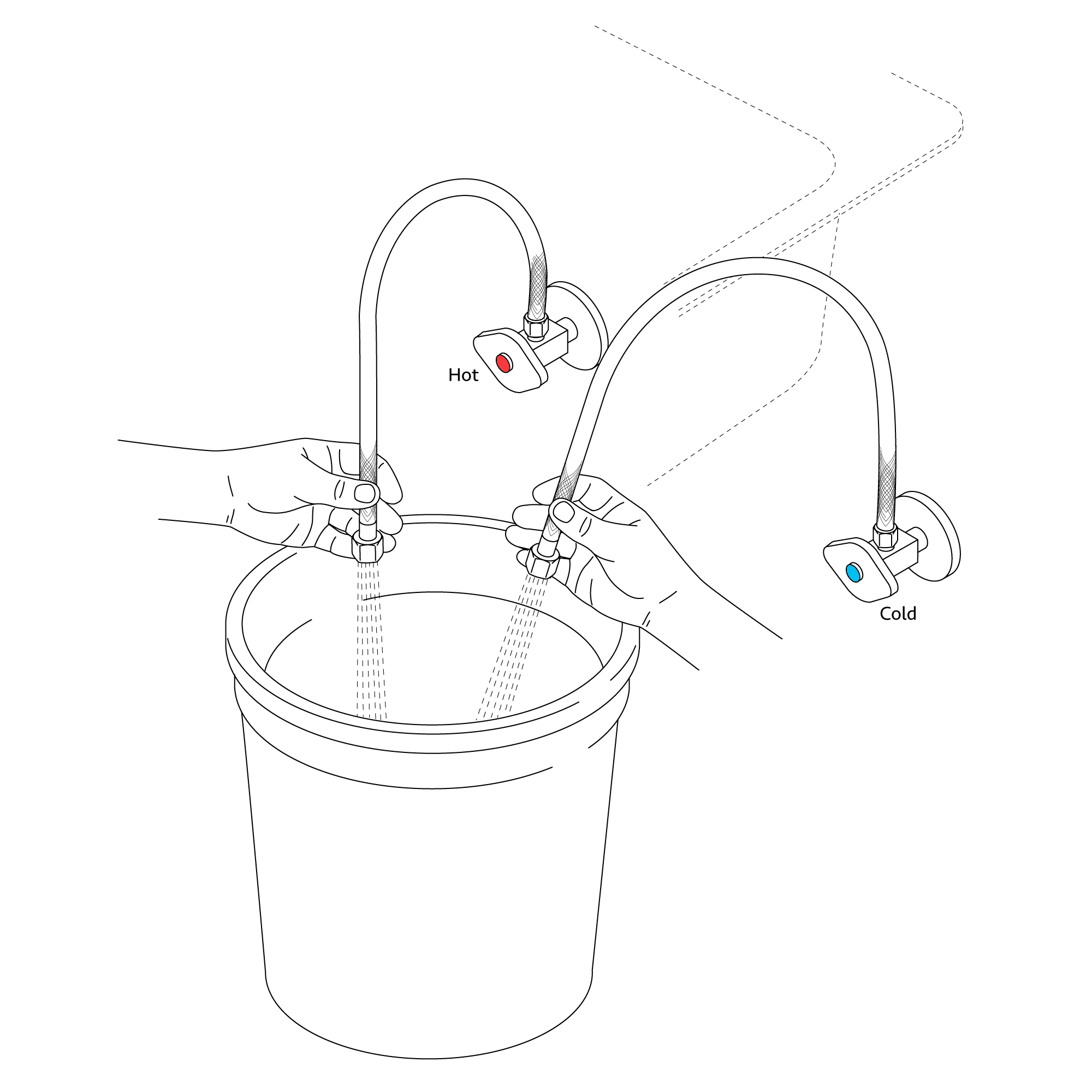

| Water Connection | | Hot & Cold Water Connection |

| control

box |

| | | |

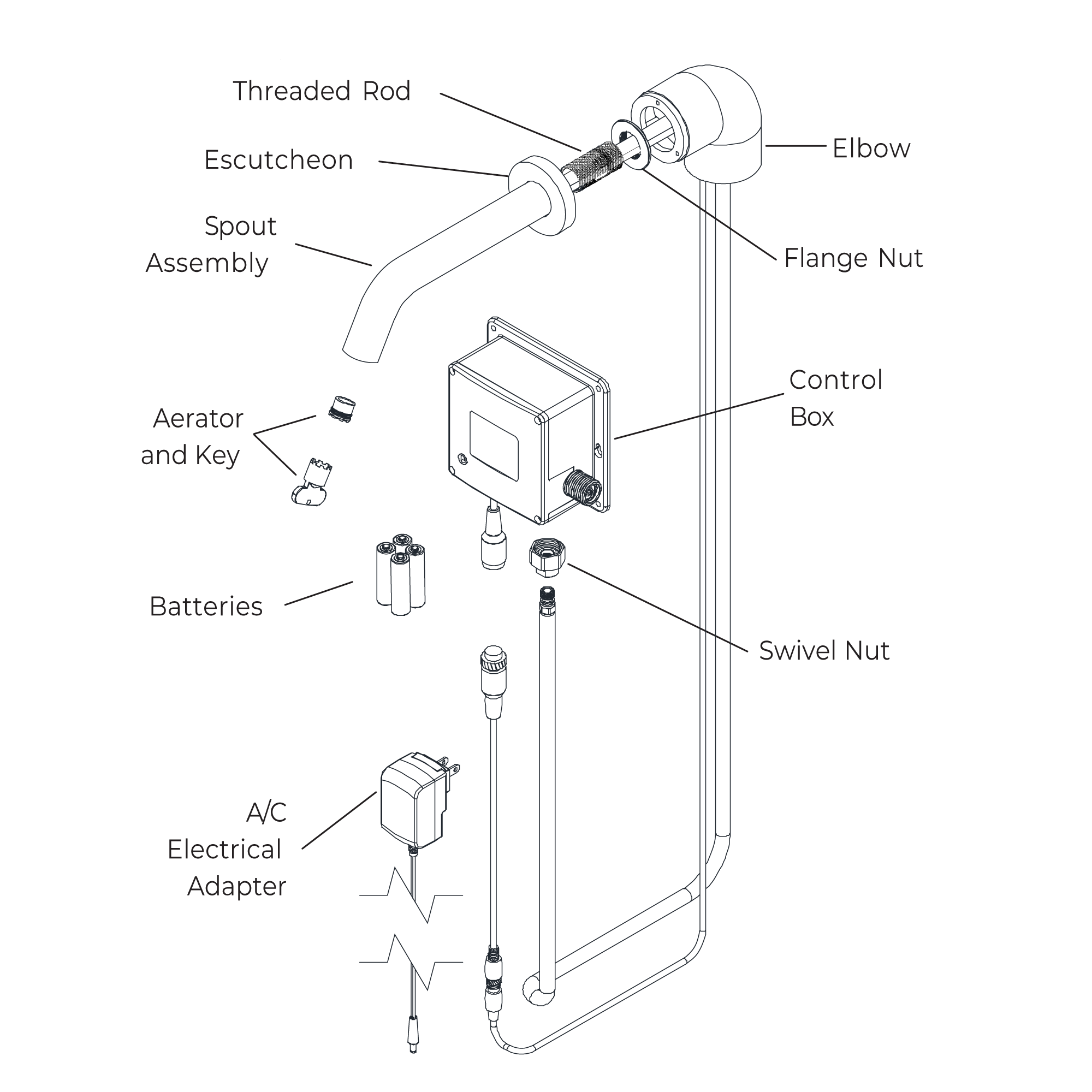

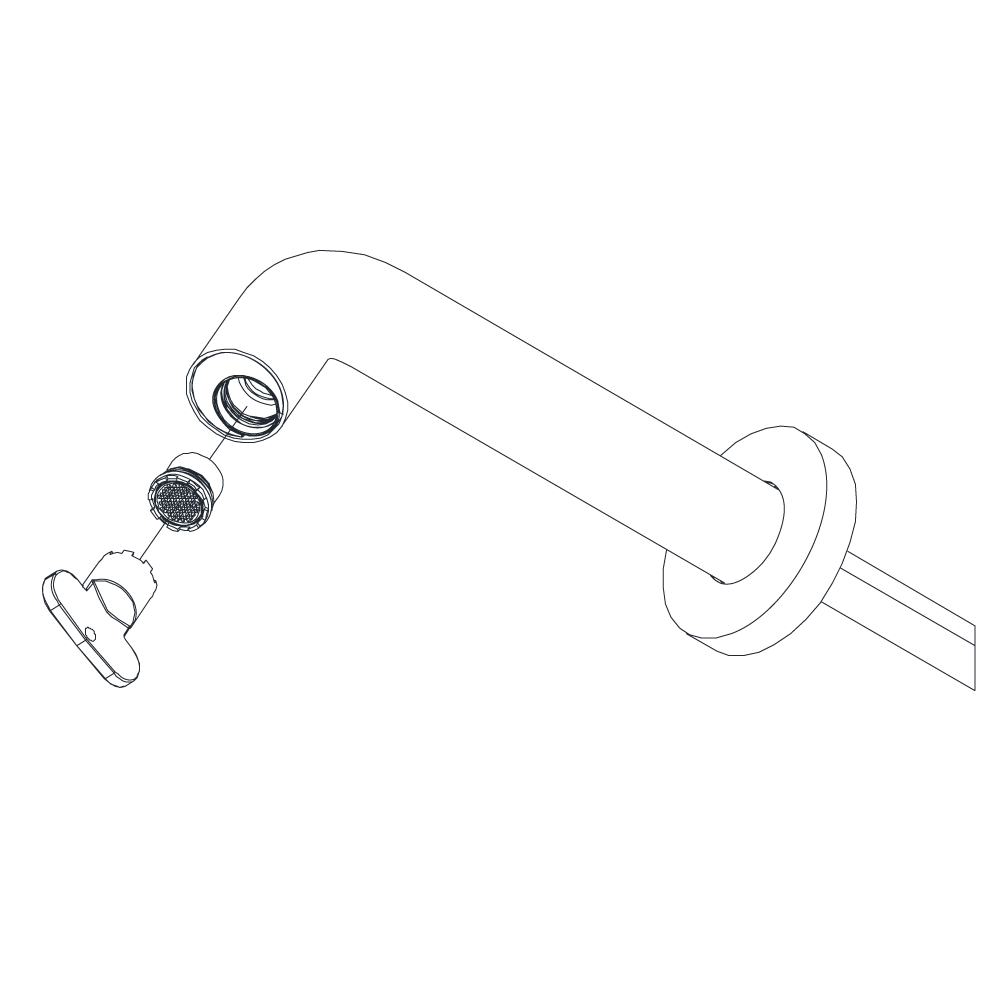

1. Carefully screw aerator into spout using the included tool.

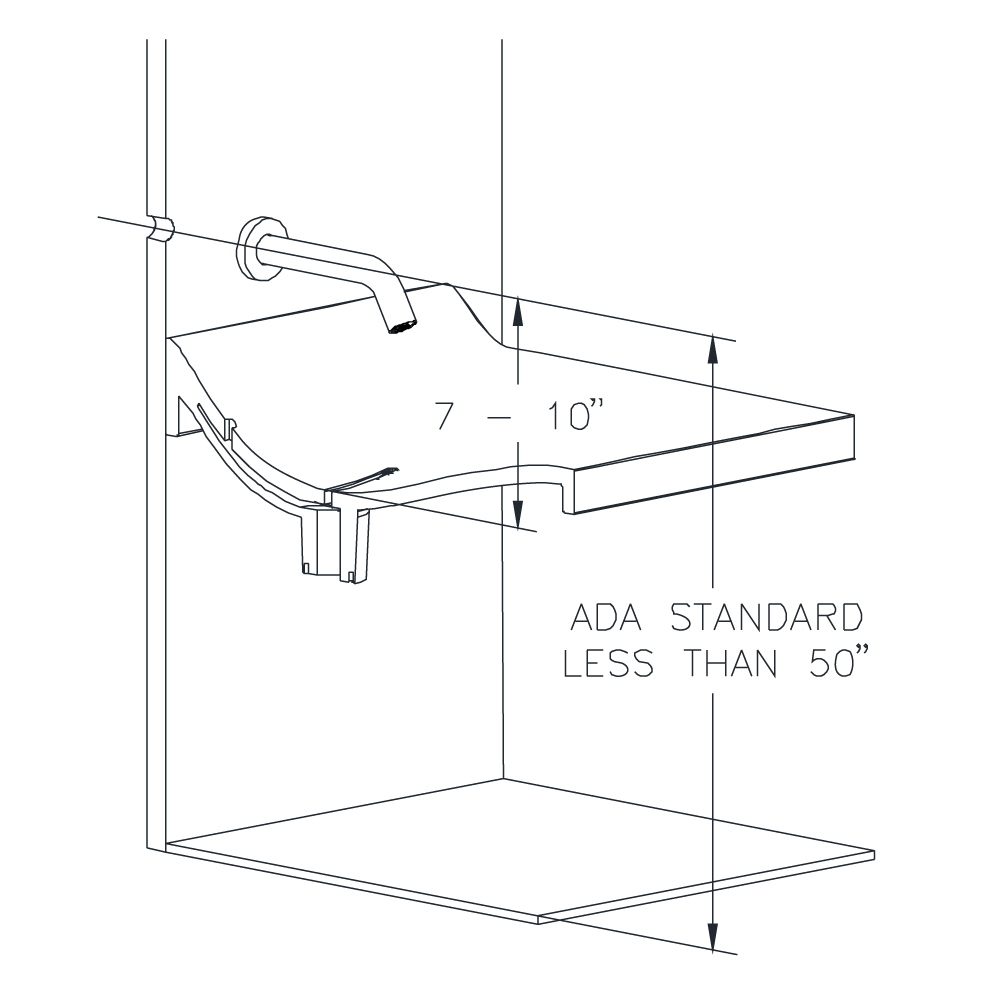

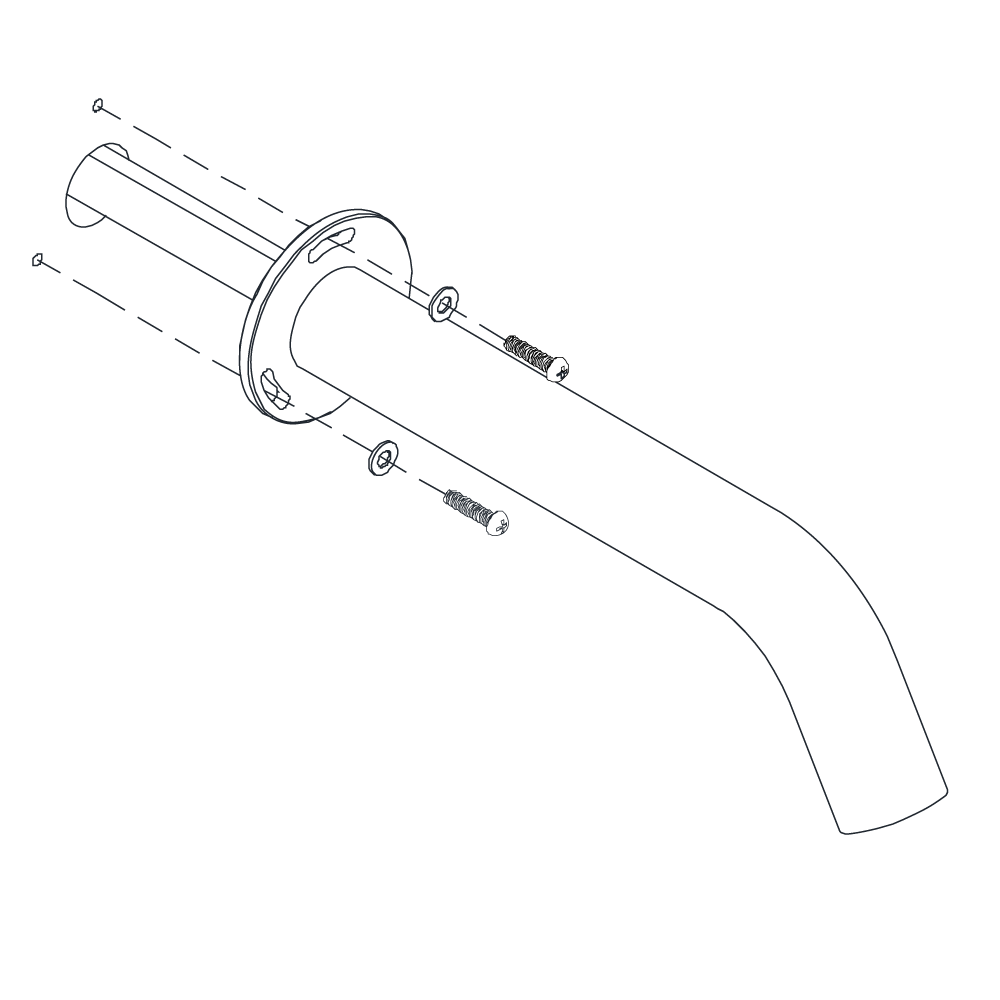

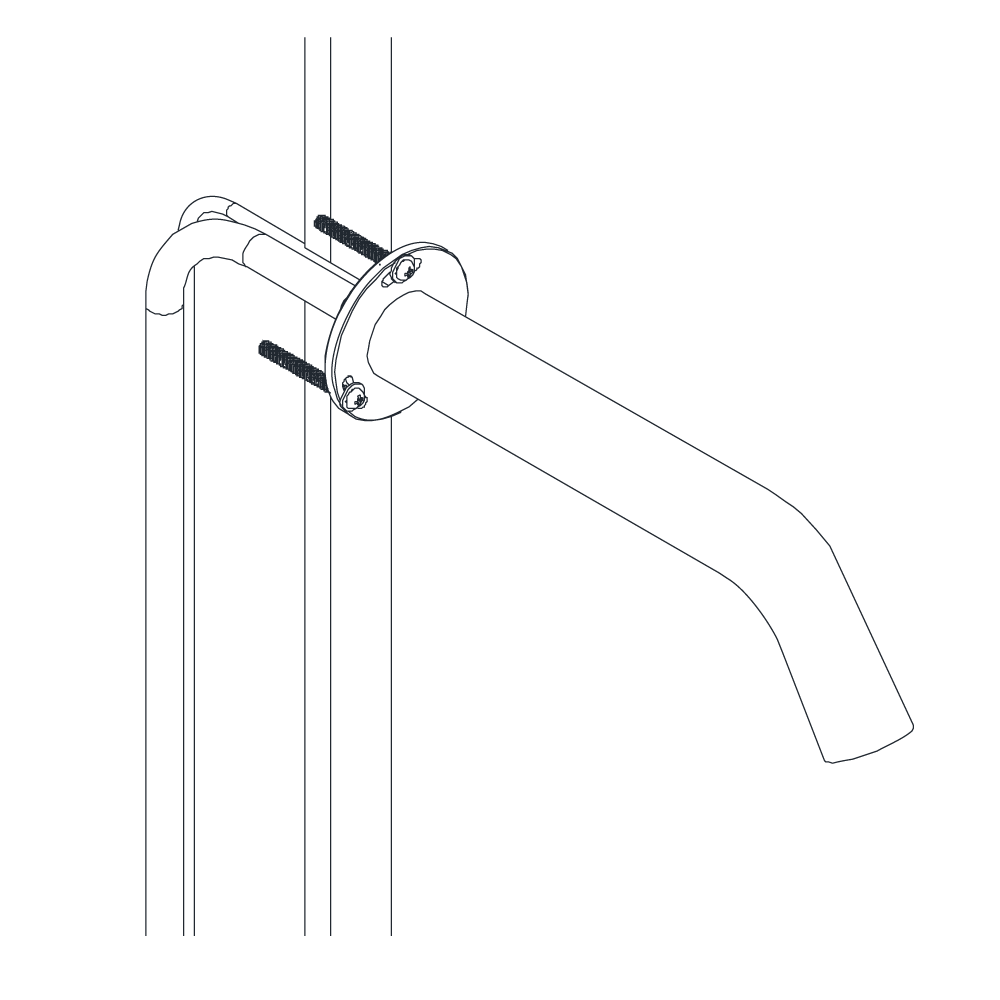

2. Mark center-point of faucet spout and drill a 3/4â hole on the previously marked center-point.

Note: It is recommended to horizontally align faucet spout with the center of the sink drain and vertically 7-10â above the sink drain. To comply with ADA standards, faucet spout must be mounted less than 50" from the finished floor.

3. There are four methods of securing the spout to the wall:

a. Drywall Anchor Method: Mark the slots of the spoutâs flange and drill 3 equally-spaced 3/16â (4mm) holes. Insert the drywall anchors into the holes. Feed the hose and sensor cable through the hole in the wall, starting with the sensor cable first. Then, attach the spout to the wall using the supplied screws.

b. Threaded Shaft Method: Thread on the threaded rod onto the faucet spout. Feed the hose and sensor cable through the hole in the wall, starting with the sensor cable first. Then, attach the flanged nut onto the threaded shaft of the spout by hand, behind the wall. Ensure the spout is correctly oriented into the basin and continue tightening the nut with a wrench. Note: Avoid over-tightening to prevent damage to the wall.

c. Elbow Method: Mark the slots of the spoutâs flange and drill 3 equally-spaced holes with a minimum drill bit size of 3/16" (4mm). Slip the sensor cabling and flexible hose through the elbow such that the brass on the elbow contacts the backside of the wall. Thread the M4 screws through the spout flange and into the threaded holes of the elbow. Tip: By hand, insert each screw into the threaded holes, and barely tighten. Then use a screwdriver to tighten each screw in a clockwise pattern little by little until tightened.

d. Plywood Method: If the restroom has a plywood backing of minimum 1/2â thickness behind the wall, use a hand drill to fasten the spout to the wall using the provided 3 coarse-threaded screws. Pre-drilling pilot holes are not required.

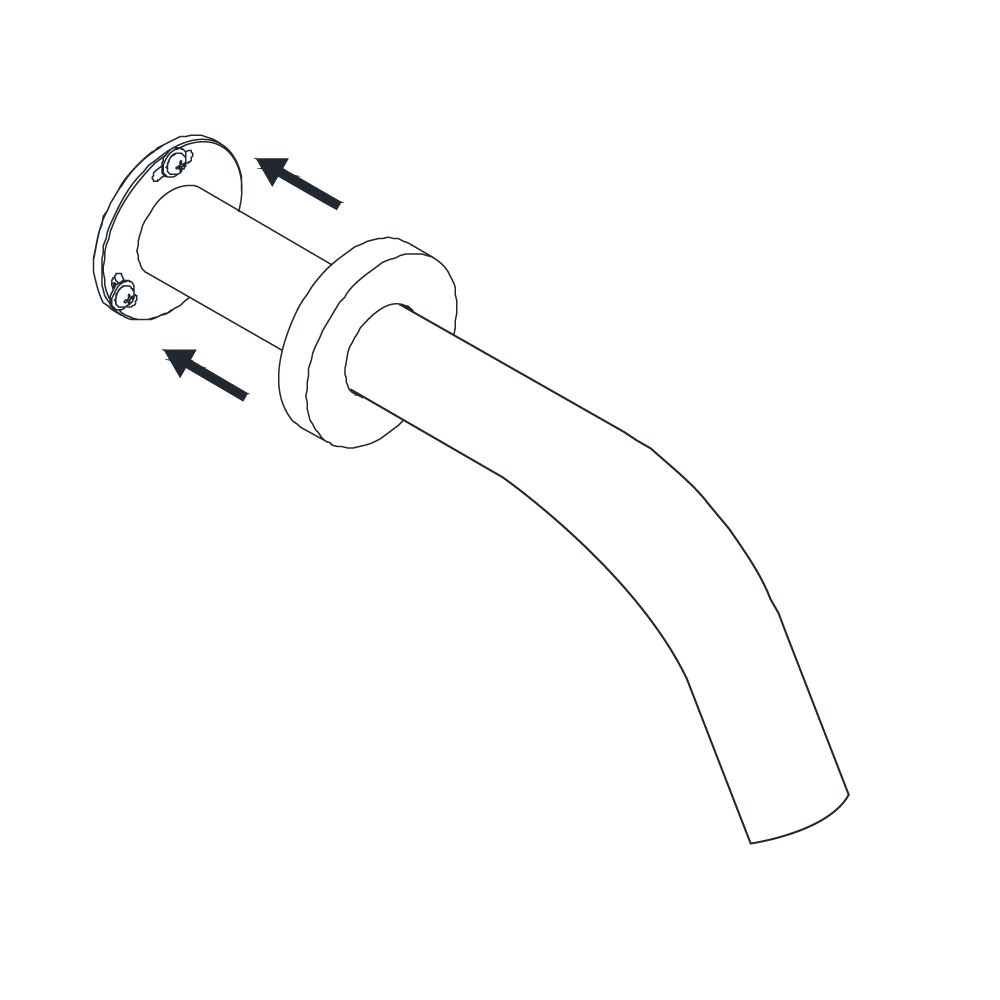

4. Slide escutcheon over the spout and onto the wall surface.

| |  | Flexible Connecting Hose

Care must be taken when connecting the flexible connection hose from the power supply box to the spout to ensure it does not bend sharply and kink or twist.

See above for recommended ways to fit the flexible connecting hose.

Important: Failure to follow these guidelines may result in poor performance and damage to the flexible connection hose. | | |

| | |

| |

| | Flush Debris from waterpipes | | Hot & Cold Regulator |

| |

|

| |

| | Control Box | | Correct way for Hose |  | | .jpg)

|

| |

|

| | |

| Step 1: | | Step 2: |

| control box |

| | | | | Step 3: | | Step 4: |

| |

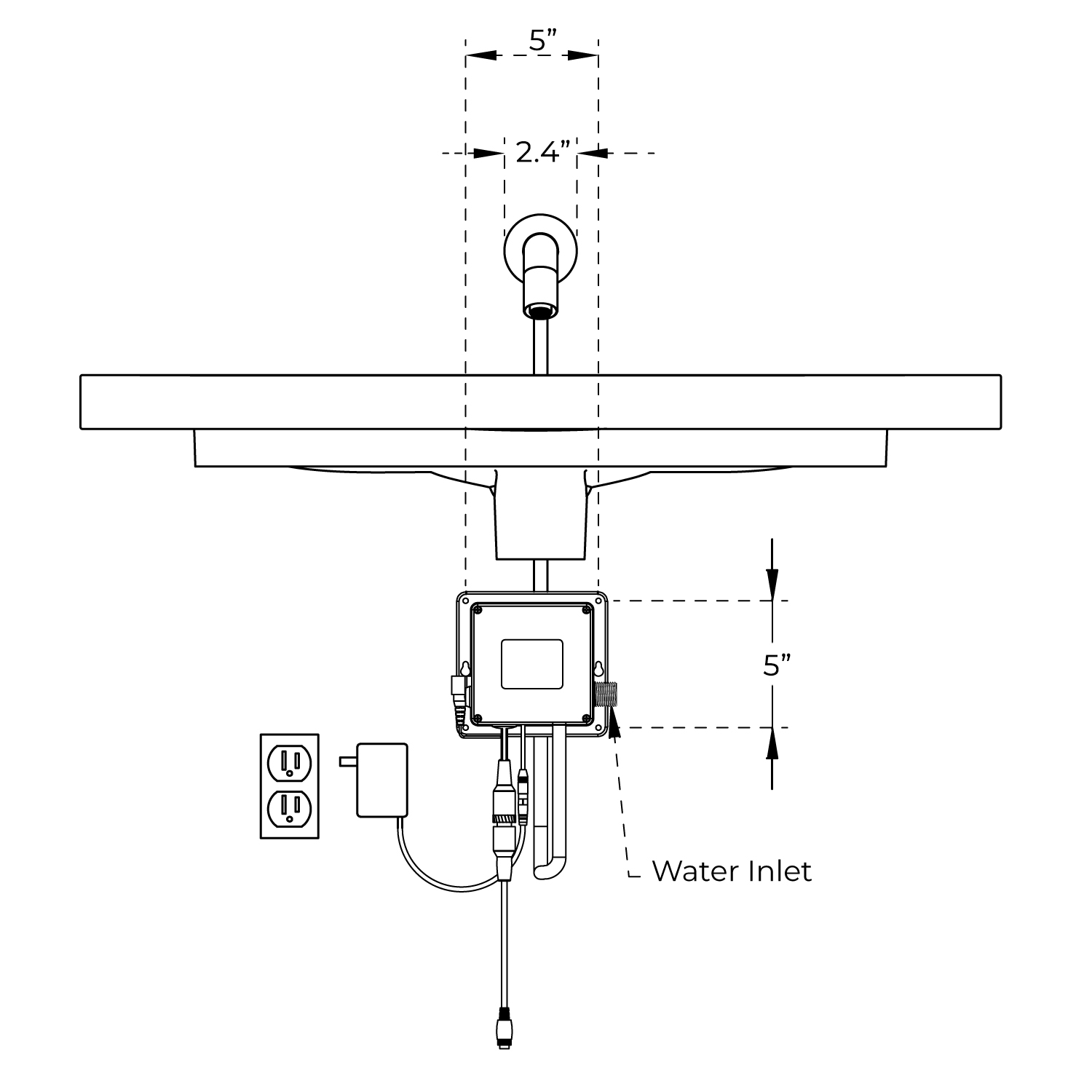

| 5" size

| | | | Step 5: | | Step 6: |

| |  |

| | |

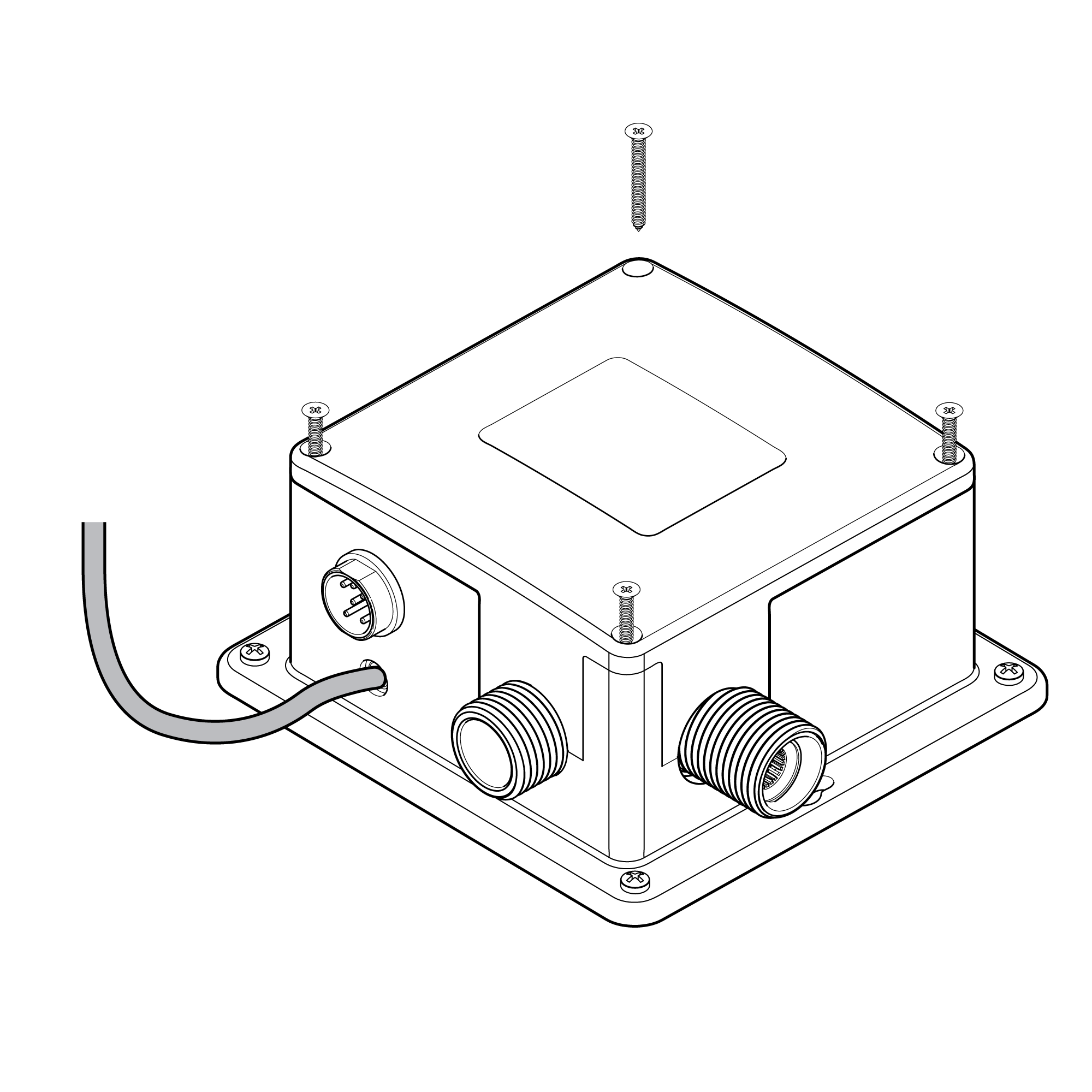

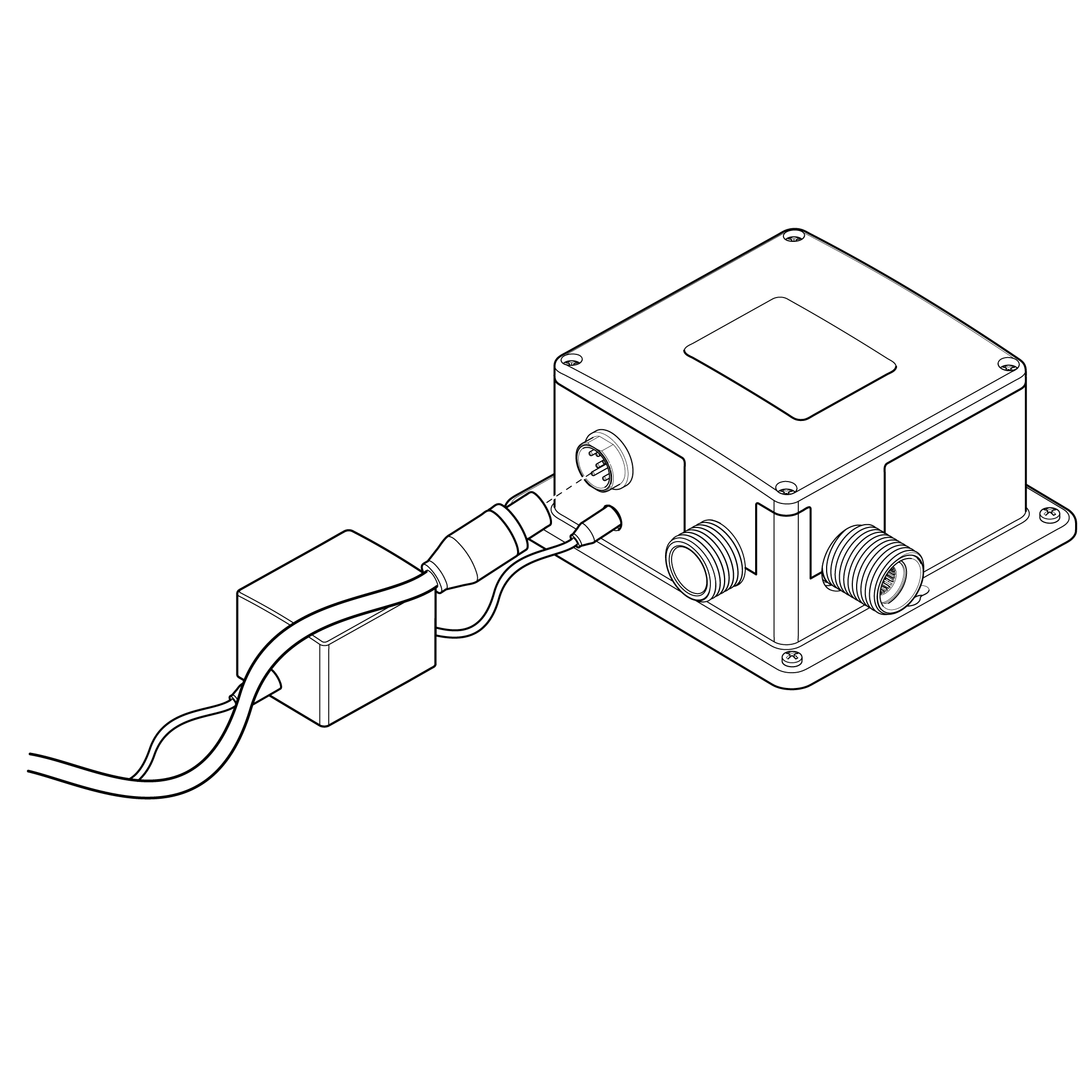

Control Box Installation

1. Remove the four screws from the control box. Remove the control box cover. Remove the battery box from the control box, and gently remove the screw from the battery box cover. Install AA batteries in the orientation shown. Note: Use only alkaline AA batteries. Re-install the battery box cover, matching the alignment arrows together. Set the battery box back into the control box, and re-install the control box cover using the previously removed screws.

2. Choose a location under the sink basin to mount the control box, such that the sensor cable, flexible hose, and incoming water supply all connect to the control box. Under the sink basin, drill a hole minimum 3/4â to fit the sensor cable and flexible hose from the spout. Feed the sensor cable and flexible hose through the hole.

3. Mount the control box to the wall in the orientation shown. Drill four 1/8" (3mm) holes, and push drywall anchors into each hole. Secure the control box to the wall with the drywall screws.

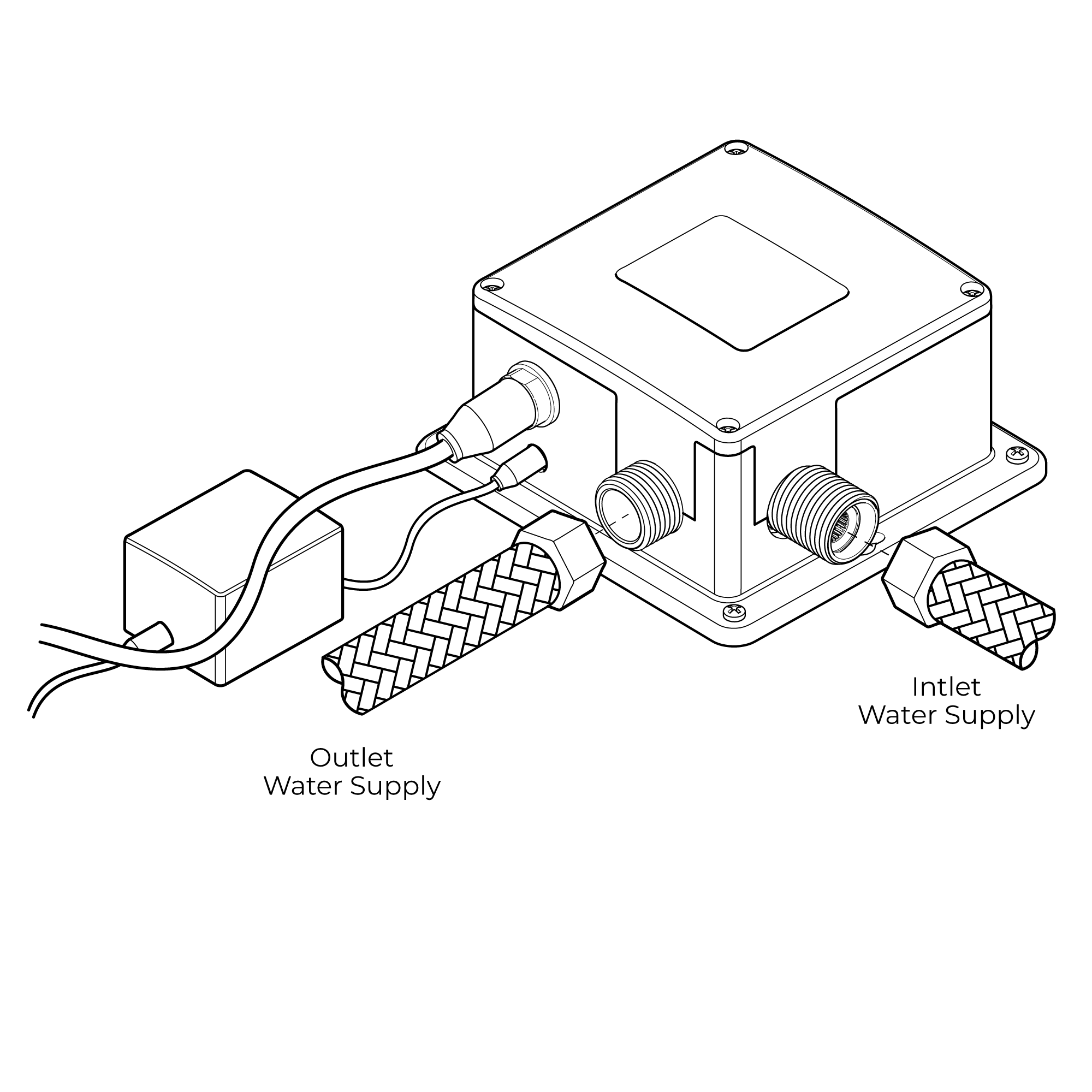

4. Connect the incoming water supply line to the control box, at the connection marked Inlet.

5. Thread on the swivel nut to the hose by hand. Tighten with a wrench.

6. Connect the faucet hose to the control box, at the connection marked Outlet.

7. Slide sensor cable connector over the sensor cable connector on the control box and tighten by hand.

Note: Prior to connecting the sensor cable to the control box, open the water supply stop valve and ensure the sink basin is completely clean and clear of objects, or the sensor will not correctly calibrate. Please wait approximately 60 seconds after connecting the sensor cable for sensor calibration to complete and to begin using the faucet.

| |  |

|

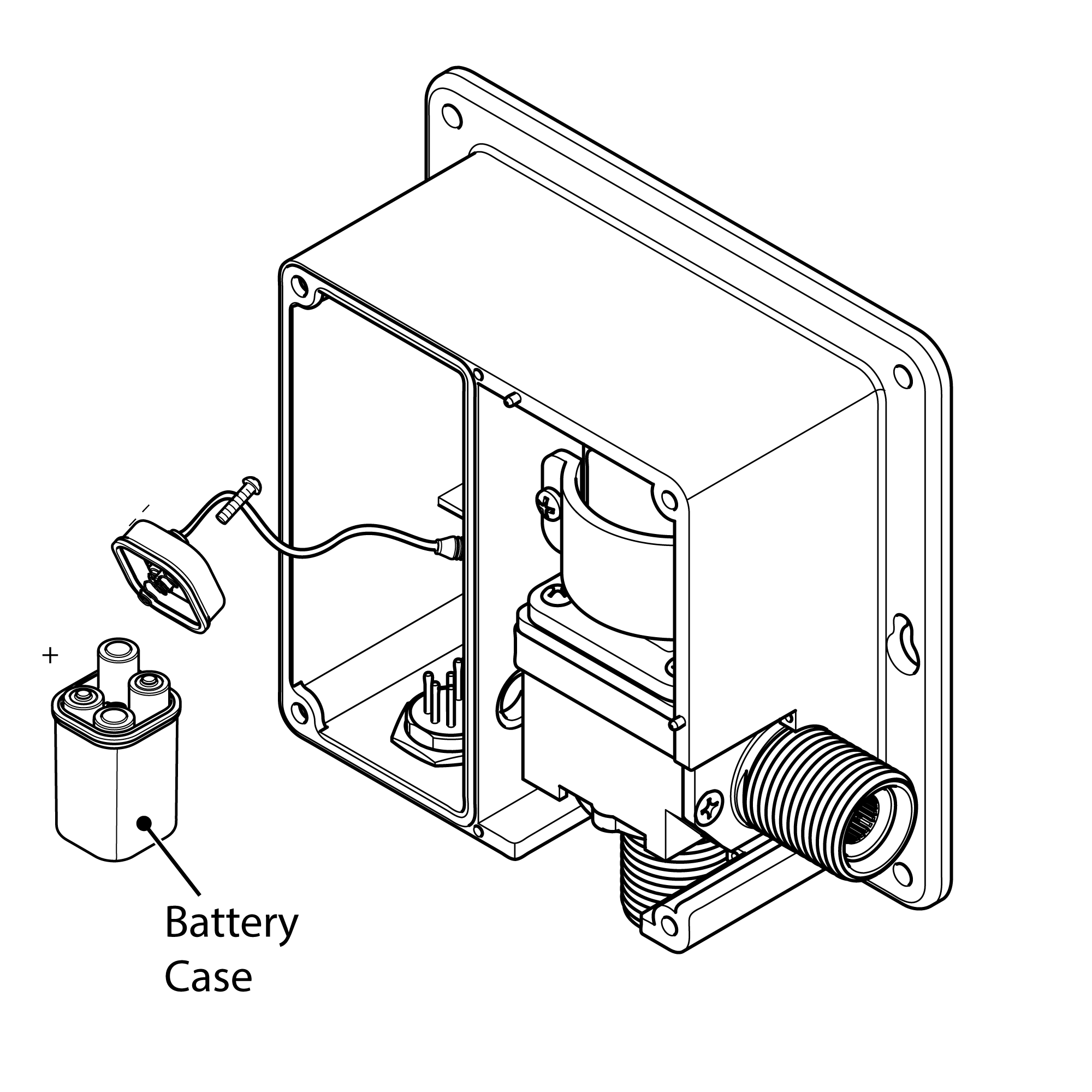

Inserting Batteries

Your infrared spout is supplied with a back up battery pack (batteries not included). In the event of a power failure the batteries will override the mains power supply to ensure the spout continues to function.

Before fitting the power supply box into position on the wall/floor, batteries (not included) will need to be fitted.

1. Remove Power Supply Box Cover - Remove all four screws in each corner of the power supply box and remove the cover.

2. Remove Battery Box - Remove the battery case from the power supply box and remove the screw in the center of the case.

3. Insert Batteries - Insert 4 x AA batteries (not included) into the battery box ensuring they are inserted the correct way.

4. Replace Battery Box - Replace the battery case cover. Replace and tighten the screw. Insert the battery case back into the power supply box.

5. Replace Power Supply Cover - Replace the power supply cover and tighten all 4 screws ensuring they are all fully tightened.

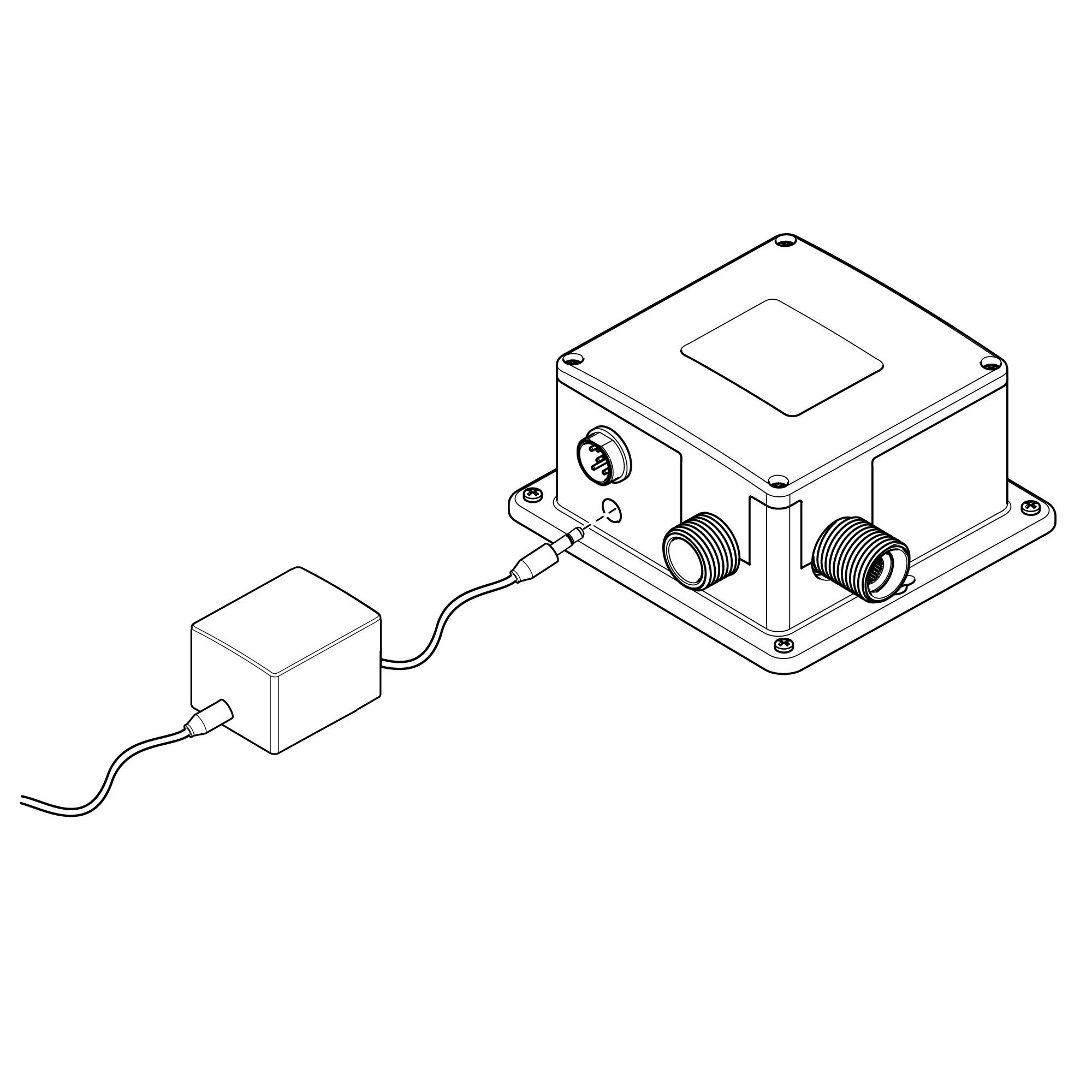

Electrical Connections

1. Position Power Supply Box - Position the power supply box onto the wall surface below the sink/work surface where it is easily accessible.

Note: Ensure that the power supply box is fitted the correct way up and that the flexible hose will reach from the underside of the spout to the power supply box.

Using suitable fixings for the wall type secure the power supply box to the wall.

2. Plug-In Power Cable - Plug the power cable into the power supply box.

3. Connect The Sensor Cable - Plug the sensor cable from the spout into the power supply box to activate the infrared senor.

Water Connections

Connecting Water Supply - A blended water supply is required to the inlet of the power supply box. Before connecting the water supply to the power supply box flush through the pipework to ensure removal of debris. Once flushed through turn off the mains water supply and close any isolating valves.

Inlet Connection - The inlet connection on the power supply box is a 1/2â BSP male threaded connection. Connect a 1/2â BSP female connector to the inlet connection ensuring a suitable sealing washer is used to create a watertight connection.

Outlet Connection - The outlet connection is a standard 1/2â BSP male threaded connection. Connect the flexi hose to the outlet connection, ensuring it is tightened fully.

Sensor Range

This machine can automatically adjust the inductive range within 10 seconds of electrification. Don't use inductor during this period in order for the inductor to automatically adjust to a suitable inductive range.

Set Water Flow Time-Out

The machine will shut off the water when washing time exceeds 1.5 minutes foreign matter induces continuously in inductive areal. If follow-up washing is needed, re-induce after removing hands for 2 seconds.

Notes

1. Please use the AA type alkaline battery (1.5v for each).

2. Fix the battery correctly. Should not be mix use the batteries with different brands, the new and old and if use non-alkaline battery, the battery life is short in 1-2 months.

3. After installation of the battery, the solenoid valve will do its self-testing.

4. After providing the power, in 10sec, the machine will self adjust the sensor distance, so during this period, do not make it work.

5. If the sensor distance is short, please move away the barrier for 5-6 mins, the machine will adjust to normal.

6. If the sensor distance from far to near, and water flows continuously, the machine will self-adjust the distance after 5 mins. | |  |

| | |

| | | | | |

|

|

|